HIROSE ELECTRIC

DF65-6S-1.7C 数据手册 ( 数据表 ) - HIROSE ELECTRIC

■ Features

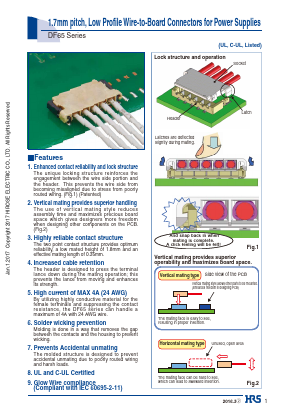

1. Enhanced contact reliability and lock structure

The unique locking structure reinforces the engagement between the wire side portion and the header. This prevents the wire side from becoming misaligned due to stress from poorly routed wiring. (Fig.1) (Patented)

2. Vertical mating provides superior handling

The use of vertical mating style reduces assembly time and maximizes precious board space which gives designers more freedom when designing other components on the PCB. (Fig.2)

3. Highly reliable contact structure

The two point contact structure provides optimum reliability, a low mated height of 1.8mm and an effective mating length of 0.35mm.

4. Increased cable retention

The header is designed to press the terminal lance down during the mating operation; this prevents the lance from moving and enhances its strength.

5. High current of MAX 4A (24 AWG)

By utilizing highly conductive material for the female terminals and suppressing the contact resistance, the DF65 series can handle a maximum of 4A with 24 AWG wire.

6. Solder wicking prevention

Molding is done in a way that removes the gap between the contacts and the housing to prevent wicking.

7. Prevents Accidental unmating

The molded structure is designed to prevent accidental unmating due to poorly routed wiring and harsh loads.

8. UL and C-UL Certified

9. Glow Wire compliance

(Compliant with IEC 60695-2-11)