ETC

C1206F104M3RACTU 데이터시트 - ETC

[Kemet]

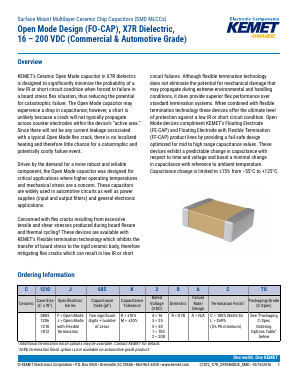

Overview

KEMET’s Ceramic Open Mode capacitor in X7R dielectric is designed to signifcantly minimize the probability of a low IR or short circuit condition when forced to failure in a board stress flex situation, thus reducing the potential for catastrophic failure. The Open Mode capacitor may experience a drop in capacitance; however, a short is unlikely because a crack will not typically propagate across counter electrodes within the device’s “active area.” Since there will not be any current leakage associated with a typical Open Mode flex crack, there is no localized heating and therefore little chance for a catastrophic and potentially costly failure event.

Benefts

• −55°C to +125°C operating temperature range

• Open Mode/fail open design

• Mid to high capacitance flex mitigation

• Lead (Pb)-free, RoHS and REACH compliant

• EIA 0805, 1206, 1210, and 1812 case sizes

• DC voltage ratings of 16 V, 25 V, 50 V, 100 V, and 200 V

• Capacitance offerings ranging from 1,000 pF to 6.8 μF

• Available capacitance tolerances of ±5%, ±10%, and ±20%

• Non-polar device, minimizing installation concerns

• 100% pure matte tin-plated termination fnish allowing for excellent solderability

• Commercial and Automotive (AEC–Q200) grades available

• SnPb termination fnish option available upon request (5% Pb minimum)

• Flexible termination option available upon request

APPLICATIONs

Typical applications include input side fltering (power plane/bus), high current (battery line) and circuits that cannot be fused to open when short circuits occur due to flex cracks. Markets include automotive applications that are directly connected to the battery and/or involve conversion to a 42 V system and raw power input side fltering in power conversion.