BKAF3-A113-40901 데이터 시트보기 (PDF) - ITT Cannon

부품명

상세내역

제조사

BKAF3-A113-40901 Datasheet PDF : 120 Pages

| |||

Assembly Procedures

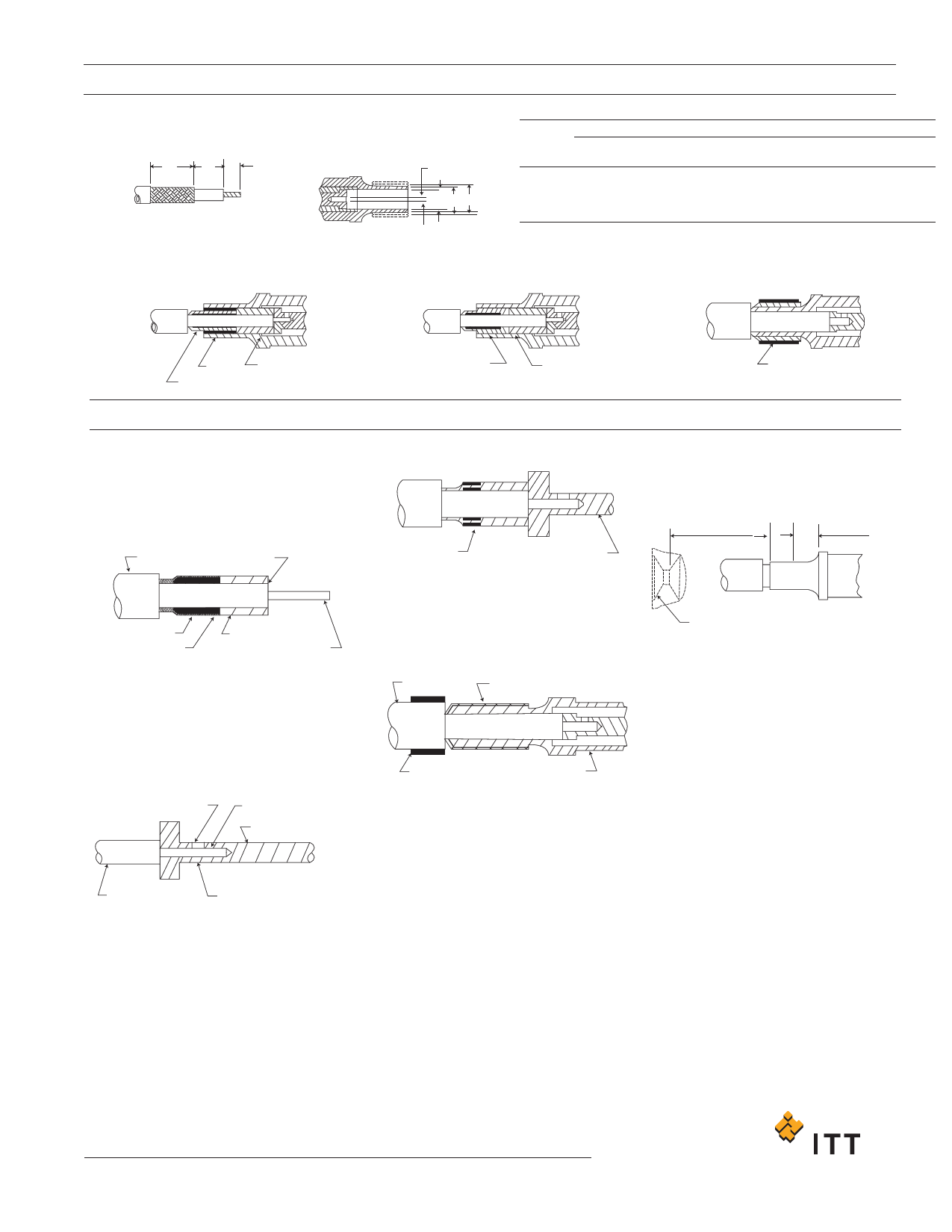

Coaxial Contact Assembly (DPGM/DPJM)

Cable Stripping

A

BC

50 Ohm Contact (RG-196U)

(assembly steps 1,

2, 3, 4, 5 & 8)

DPGM/DPJM/DPJMB

.035 DIA

(0.89)

DE F

Cable Trim Dimensions

A

B

C

150 ohm

95 ohm

75 ohm

50 ohm

3/16 (4.76)

3/16 (4.76)

3/16 (4.76)

1/4 (6.35)

1/16 (1.59)

1/8 (3.18)

1/8 (3.18)

1/8 (3.18)

5/32 (3.97)

5/64 (1.98)

5/64 (1.98)

5/64 (1.98)

Cable Entry Dimensions

D

min. dia.

E

max. dia.

F

min. dia.

.154 (3.91)

.106 (2.69)

.122 (3.10)

.106 (2.69)

.183 (4.65)

.139 (3.53)

.158 (4.01)

.136 (3.53)

.202 (5.13)

.153 (3.89)

75 Ohm Contact (RG-187U)

(assembly steps 1,

2, 3, 5 & 8)

95 Ohm Contact (RG-195U)

(assembly steps 1,

3, 6, 7 & 8)

SHIM

CRIMP RING

Assembly Steps

BUSHING

CRIMP RING

BUSHING

1 . After the coaxial cable has been stripped to the

proper dimensions, tin the center conductor. If

O.D. of cable is less than .096 (2.44), slip

rubber bushing over wire. (50, 75 & 95 ohm)

2. Assemble crimp ring under braid and add bush-

ing to cable. (50 & 75 ohm)

JACKET

DIELECTRIC

CRIMP RING

BRAID

BUSHING

CENTER CONDUCTOR

3. The center contact is supplied loose in the

polyethylene bag. Insert the tinned conductor

into the contact. Wire must be visible through

inspection hole and dielectric pushed against

contact shoulder. For 150 ohm contact shoulder

must be flush against bushing. Heat contact

with a clean soldering iron. Avoid solder outside

contact, (50, 75, & 95 ohm)

INSPECTION HOLE

CENTER CONDUCTOR

CENTER CONTACT

4. Wrap shim around braid. (50 ohm)

SHIM

CENTER CONTACT

5. Feed cable and assembled parts into coaxial

shell. Care is required if braid is to fit smoothly

inside the shell. (50 & 75 ohm)

6. Thread crimp ring over cable. Feed center con-

tact into coaxial shell with the shell between the

dielectric and the braid. (95 ohm)

JACKET

BRAID

CRIMP RING

SHELL

CRIMP RING

7. Slip crimp over the braid. (95 ohm)

8. Crimp - crimp tool must be located 1/16

(1.58) to 5 / 64 (1.98) from shoulder of coaxial.

(50, 75 & 95 ohms)

.125 (3.18) MIN. PLUG

.063 (1.59) MIN. RECPT

.063 (1.59) EDGE OF

.078 (1.98) CRIMP TOOL

SEALING GROMMET LOACATION

DIELECTRIC

APPLY CLEAN SOLDERING IRON

Dimensions shown in inch (mm)

Specifications and dimensions subject to change

www.ittcannon.com

103