TE Connectivity

YR1B301KCC Datasheet - TE Connectivity

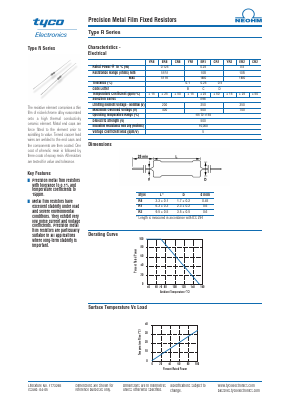

The resistive element comprises a thin film of nickel-chrome alloy evaporated onto a high thermal conductivity ceramic element. Metal end caps are force fitted to the element prior to spiralling to value. Tinned copper lead wires are welded to the end caps and the components are then coated. One coat of phenolic resin is followed by three coats of epoxy resin. All resistors are tested for value and tolerance.

Key Features

■ Precision metal film resistors

with tolerance to 0.1% and

temperature coefficients to

15ppm.

■ Metal film resistors have

excellent stability under load

and severe environmental

conditions. They exhibit very

low noise current and voltage

coefficients. Precision metal

film resistors are particularly

suitable in all applications

where long-term stability is

important.