STMicroelectronics

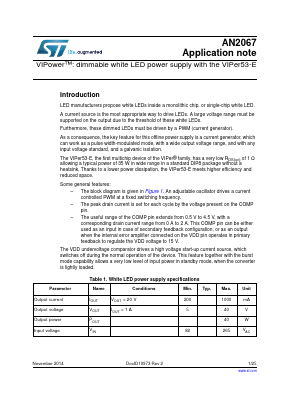

AN2067 Datasheet - STMicroelectronics

Introduction

LED manufacturers propose white LEDs inside a monolithic chip, or single-chip white LED.

A current source is the most appropriate way to drive LEDs. A large voltage range must be supported on the output due to the threshold of these white LEDs.

Furthermore, these dimmed LEDs must be driven by a PWM (current generator).

As a consequence, the key feature for this offline power supply is a current generator, which can work as a pulse width-modulated mode, with a wide output voltage range, and with any input voltage standard, and a galvanic isolation.

The VIPer53-E, the first multichip device of the VIPer® family, has a very low RDS(on) of 1 Ω allowing a typical power of 35 W in wide range in a standard DIP8 package without a heatsink. Thanks to a lower power dissipation, the VIPer53-E meets higher efficiency and reduced space.

Some general features:

– The block diagram is given in Figure 1. An adjustable oscillator drives a current controlled PWM at a fixed switching frequency.

– The peak drain current is set for each cycle by the voltage present on the COMP pin.

– The useful range of the COMP pin extends from 0.5 V to 4.5 V, with a corresponding drain current range from 0 A to 2 A. This COMP pin can be either used as an input in case of secondary feedback configuration, or as an output when the internal error amplifier connected on the VDD pin operates in primary feedback to regulate the VDD voltage to 15 V.