XS2F-D421-S077 View Datasheet(PDF) - Unspecified

Part Name

Description

MFG CO.

XS2F-D421-S077 Datasheet PDF : 28 Pages

| |||

Pin Block

(Screw-mounting Connectors)

Cover

Triangle mark

Cover lock Pin block

• Align the triangular marks on the pin block and cover and

insert the pin block into the cover.

• Press them together firmly (0.39 to 0.49 N·m) until the pin

block does not come out of the cover.

(5) Mounting Cap

• After mounting the cover to the pin block and the cover

snaps into place, tighten the cap securely by hand within a

torque of 0.39 and 0.49 N·m.

Note: If the cap is not tighten securely enough, the degree of protection (IP67)

may not be maintained or vibration may cause the cap to become loose.

Do not tighten the cap with pliers or similar tools; they may damage the

cap.

A Cap

• After fully tightening the cap, length A should be

approximately one of the following according to the cable

external diameter and the Connector model.

Connector

For 6-mm-dia. cable

For 4-mm-dia. cable

For 3-mm-dia. cable

Cable external diameter (mm)

6 mm 5 mm 4 mm 3 mm

1

0

---

---

---

2

1

---

---

---

2

1

(6) After Assembly

• Confirm the insulation between cores after completing

assembly.

Recommended Cables

When connecting a commercially available cable to a

connector assembly, use a cable with an outside diameter of

3 to 6 mm and core sizes of 0.18 to 0.75 mm2 for crimping

connectors and 0.5 mm2 maximum for soldering connectors.

Connector Arrangement

For safety, when constructing a connection system between a

Sensor and panel with a connector, make sure that the

connector plug is on the Sensor side and the connector socket

is on the panel side (i.e., the female pins are located on the

power-supply side).

Sensor Side

Connecting Cable

Panel Side

(Power-supply Side)

Safety Precautions

XS2

Precautions for Correct Use

Do not use the product in atmospheres or environments that

exceed product ratings.

Tightening Cap (Connector Assemblies)

1. Do not use pliers to tighten caps, otherwise the caps may

be damaged. Be sure to tighten each cap by hand within a

torque range between 0.39 and 0.49 N·m.

2. If caps are not tightened securely, the Connectors may not

maintain their proper degree of protection (i.e., IP67) or the

caps may become loose due to vibration.

Connector Connection and Disconnection

• When connecting or disconnecting Connectors, be sure to

hold the Connectors by hand.

• Do not hold the cable part when disconnecting Connectors.

• Connectors mating with sockets must be fully inserted into

the sockets. Tighten the thread bracket carefully so that the

threads will not be damaged.

• Fully tighten thread bracket within a torque range between

0.39 and 0.49 N·m and be sure that the threads of the

opposite parts are hidden by the thread bracket.

• When disconnecting Connectors, be sure to loosen the

thread brackets first. Do not loosen the caps.

• Thread brackets must be loosened in the cutout direction.

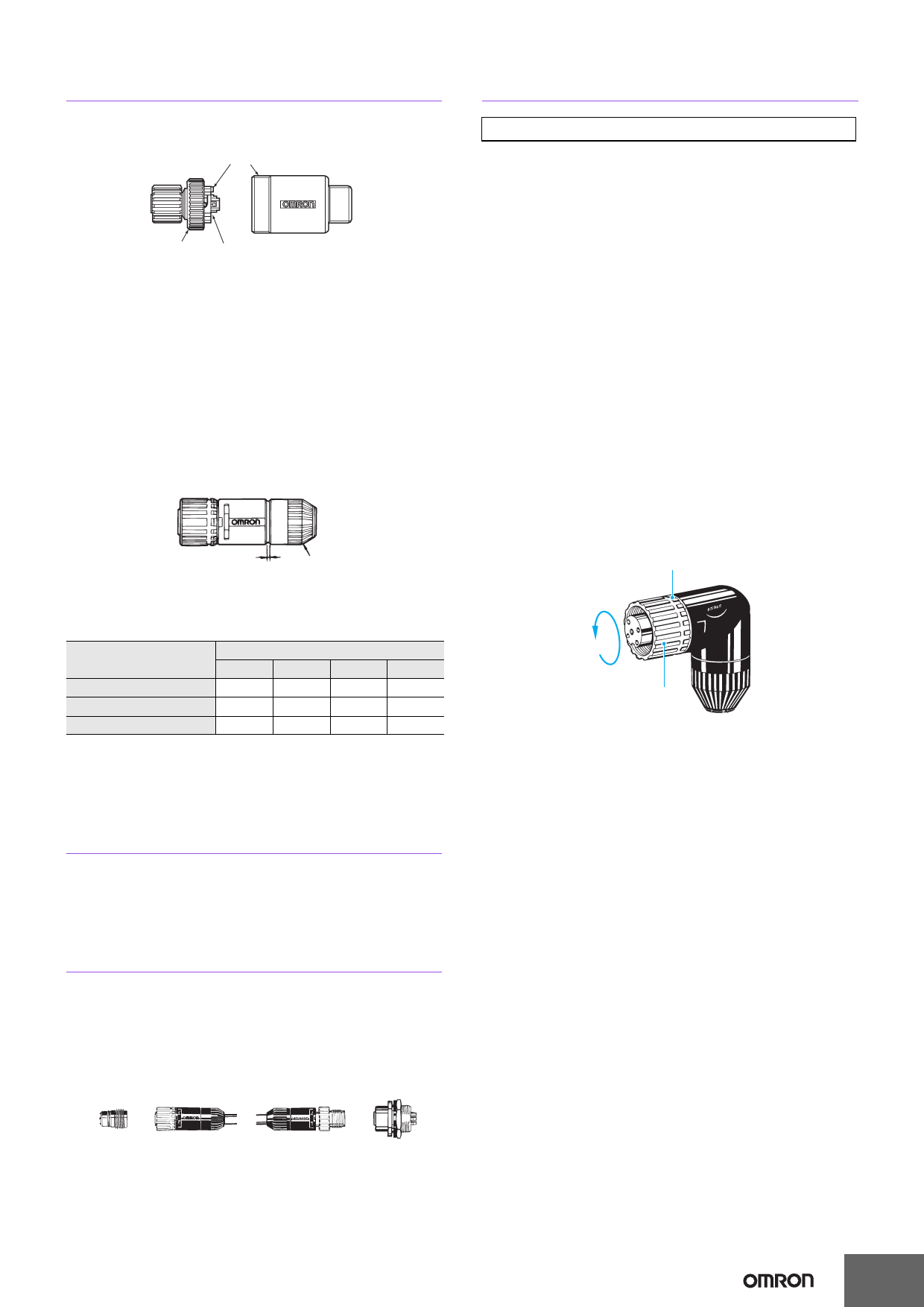

Cutout

Loosen

Thread

bracket

Degree of Protection

• Do not impose external force continuously on the joints of

pin blocks and covers, otherwise the Connectors may not

keep its proper degree of protection (i.e., IP67).

• The degree of protection of connectors (IP67) is not for a

fully watertight structure. Do not use them underwater.

• Connectors are of resin mold construction. Do not impose

excessive force on them.

Setup

• Do not make any cable bends near the base of the Unit.

• Any bends made must have a minimum radius of 40 mm.

(Plug)

(Socket)

(Plug)

(Socket)

26