B/G-BOX View Datasheet(PDF) - 3M

Part Name

Description

View to exact match

B/G-BOX Datasheet PDF : 4 Pages

| |||

B/G+ Wire Connector

LISTED

314R

Data Sheet

Application

Use a 3M™ B/G+ Wire Connector to

electrically connect two or more

conductor ends in a pigtail application

and insulate the connection.

Wire

AWG Range

COPPER conductors only, No. 14 thru

No. 6 sol. and/or str.

METRIC Range

COPPER conductors only, 2,5 mm2

thru 10,0 mm2 ridged (solid or

stranded) and flexible.

(see wire matrix for specific wire

combinations)

Construction

Spring

Spring steel, corrosion resistant coating

Insulator

Flame retardant, polypropylene and

thermoplastic elastomer, color coded

blue/gray

Weight

.0124 lbs. (5,647 g)

Performance Test

The following tests were performed to

the specification of UL Standard 486C

and CSA Standard C22.2 No.

188–M1983.

Static–Heating

Pass

Secureness

Pass

Pullout

Pass

Dielectric Voltage Withstand Pass

Secureness–Of–Insulation

Pass

Flammability

Pass

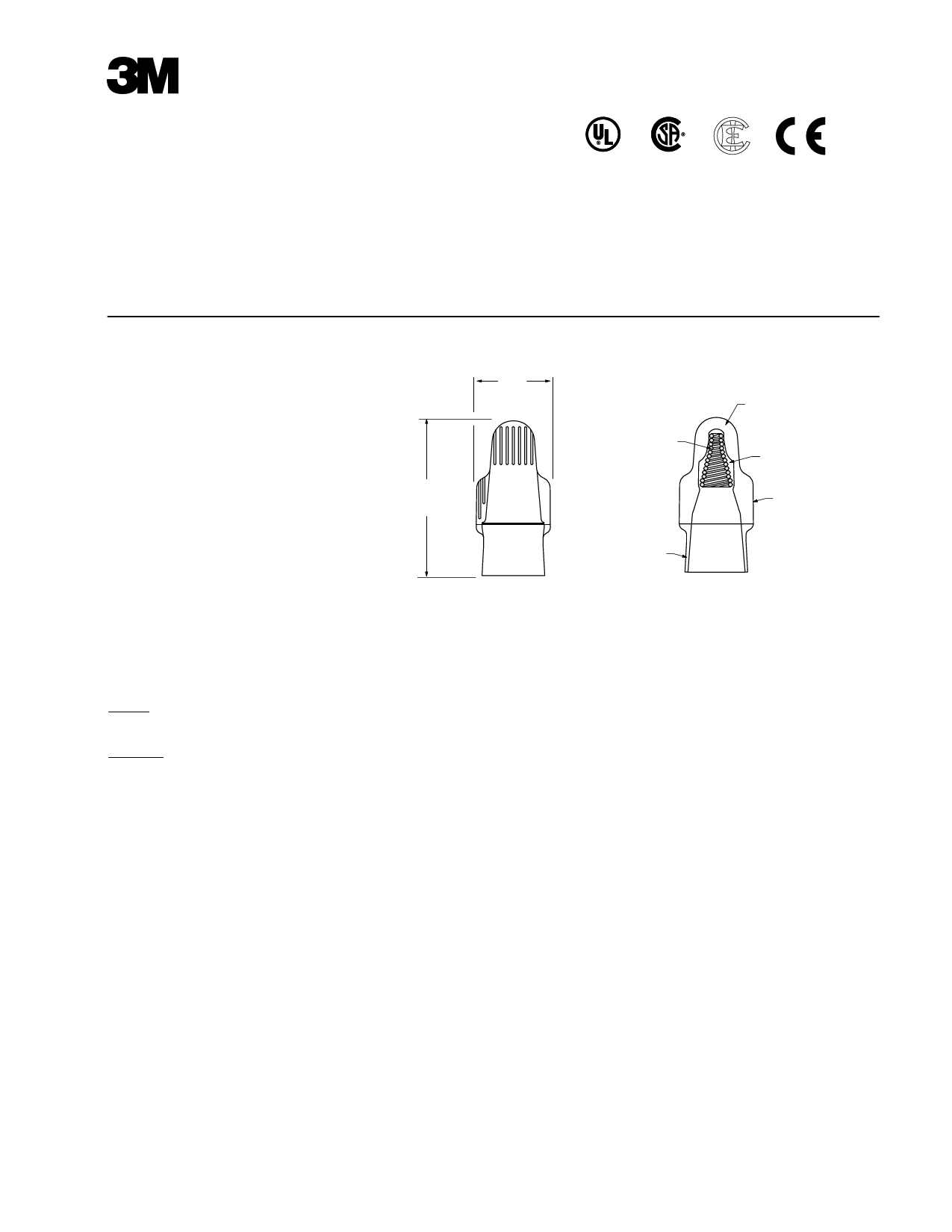

1.12

1.79

Full Length

ÉÉÉÉ Live Action

Expandable

ÉÉÉÉ Steel Spring

ÉÉÉÇÉÉÉÉÉÉÇÉÉÉ Flexible

ÇÇ ÇÇ Skirt

Top For

Spin-on

Free

Expansion

Space

Spin-On

Wings

Other Test

Salt Spray

Pass

Per MIL–STD–1344A Method 1001.1

Vibration

Pass

Per MIL–STD–1344A Method 2005.1

UV Exposure

Pass

Per ASTM G–53–77

Fluid Immersion Test

Connectors were immersed in the

following chemicals for seven days at

23_C 2_C with no affect on

appearance or loss of material strength.

Typical Reagents and Materials

From ASTM D 543–87 and

MIL–STD–1344A

Acetic Acid

Acetone

Detergent Solution, Heavy Duty

Ethyl Alcohol (95%)

Ethyl Alcohol (50%)

Heptane

Hydrogen Peroxide Solution 28%

Methyl Alcohol

Sodium Hydroxide Solution

Mineral Spirit

Lubricating Oil

Engineering Specification

3M B/G+ wire connector is capable of

connecting two or more wires in a

pigtail application, in the wire range of

No. 14 thru No. 6 AWG solid and/or

stranded copper conductors. The

connector shall be constructed of an

active (live) spring. With a corrosion

resistant coating. The connector shall

be UL LISTED and CSA Certified as a

pressure wire connector. The connector

shall be voltage rated 600 volts

maximum, building wire, 1000 volts

maximum, signs, lighting fixtures

(luminaries). The connector shall have

a maximum operating temperature of

105_C (221_F).

Regulatory Agencies

UL Listed

as a Pressure Wire Connector tested

per UL Standard 486C

UL File No. E23438

OPERATING TEMPERATURE:

105_C (221_F)

VOLTAGE RATING:

600 volts max. building wire

1000 volts max. signs, lighting fixtures

(luminaries)

FLAMMABILITY RATING:

UL94 V–2