DEHR33D102KA3B View Datasheet(PDF) - Unspecified

Part Name

Description

View to exact match

DEHR33D102KA3B Datasheet PDF : 74 Pages

| |||

!Note • Please read rating and !CAUTION (for storage, operating, rating, soldering, mounting and handling) in this catalog to prevent smoking and/or burning, etc.

• This catalog has only typical specifications. Therefore, please approve our product specifications or transact the approval sheet for product specifications before ordering.

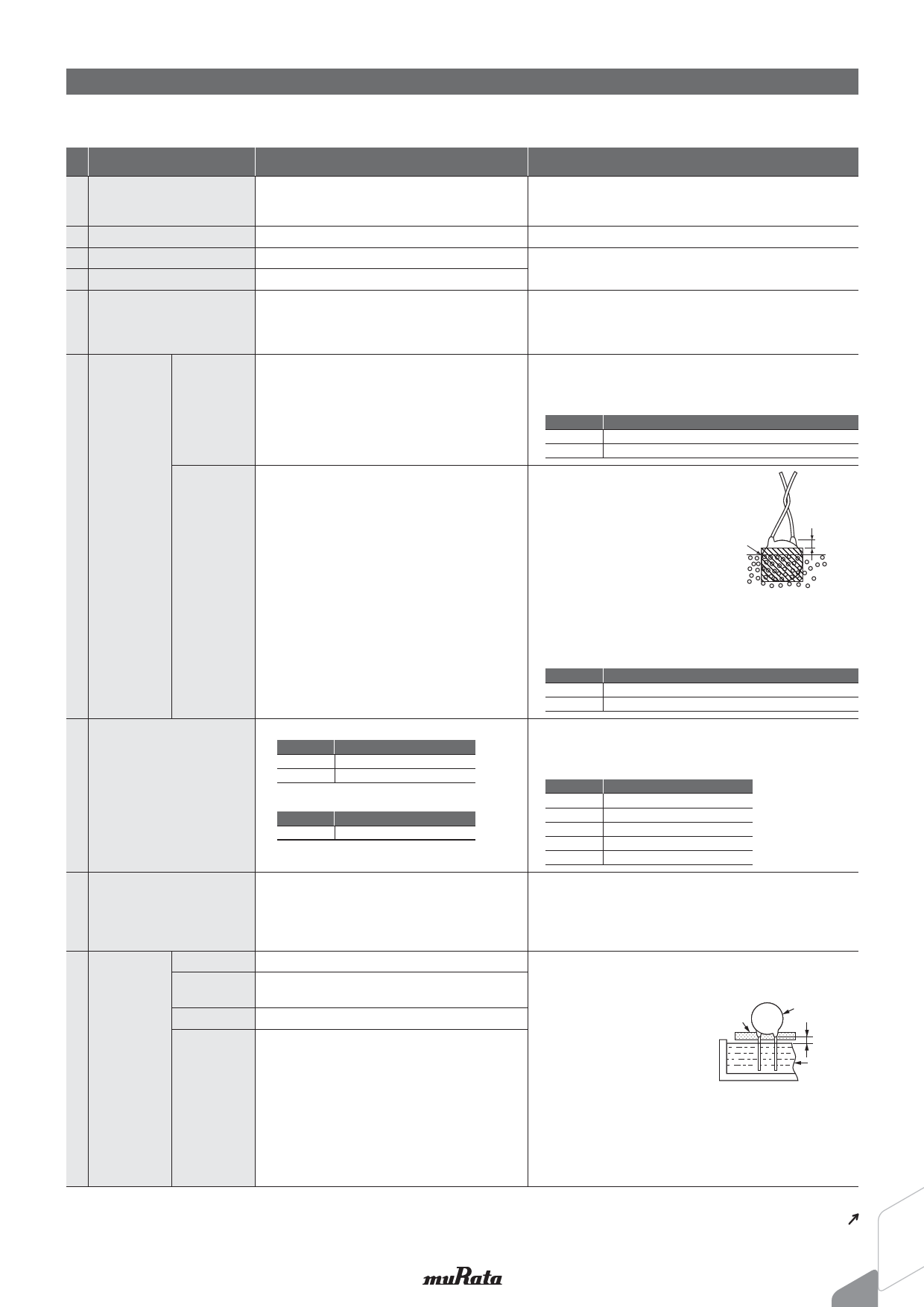

Type SA: AC400V / RA: AC500V Specifications and Test Methods

C85E.pdf

Sep.14,2018

Operating Temperature Range: -40 to +125°C

No.

Item

Specifications

Test Method

1 Appearance and Dimensions

2 Marking

3 Capacitance

4 Dissipation Factor (D.F.)

No visible defect, and dimensions are within

specified range.

To be easily legible

Within specified tolerance

2.5% max.

5 Insulation Resistance (I.R.)

10000MΩ min.

Between Lead

Wires

No failure

The capacitor should be visually inspected for evidence of

defect.

Dimensions should be measured with slide calipers.

The capacitor should be visually inspected.

The capacitance, dissipation factor should be measured at

20˚C with 1±0.1kHz and AC1±0.2V max.

The insulation resistance should be measured with

DC500±50V within 60±5s of charging.

The voltage should be applied to the capacitor through a

resistor of 1MΩ.

The capacitor should not be damaged when the test voltages

from Table 1 are applied between the lead wires for 60s.

Type

SA

RA

<Table 1>

Test Voltage

AC2600V(r.m.s.) ‹50/60Hz›

AC4000V(r.m.s.) ‹50/60Hz›

6

Dielectric

Strength

Body

Insulation

No failure

First, the terminals of the capacitor

about

should be connected together. Then,

as shown in the figure at right, a metal

foil should be closely wrapped around

the body of the capacitor to the

distance of about 3 to 4mm (in case of

Metal

Foil

3 to 4mm

(in case of

Type RA:

3 to 6mm)

Type RA: 3 to 6mm) from each terminal.

Then, the capacitor should be inserted

into a container filled with metal balls

Metal

Balls

of about 1mm diameter. Finally, AC

voltage from Table 2 is applied for 60s between the capacitor

lead wires and metal balls.

Type

SA

RA

<Table 2>

Test Voltage

AC2600V(r.m.s.) ‹50/60Hz›

AC4000V(r.m.s.) ‹50/60Hz›

7 Temperature Characteristics

Char.

Capacitance Change

B

Within ±10%

E

Within

% +20

–55

(Temp. range: -25 to +85°C)

Char. Temperature Coefficient

SL

+350 to -1000ppm/°C

(Temp. range: +20 to +85°C)

The capacitance measurement should be made at each step

specified in Table 3.

Step

1

2

3

4

5

<Table 3>

Temperature (ºC)

20±2

-25±2

20±2

85±2

20±2

8 Solderability of Leads

Lead wire should be soldered with uniform coating

on the axial direction over 3/4 of the

circumferential direction.

The lead wire of a capacitor should be dipped into molten

solder for 2±0.5s.

The depth of immersion is up to about 1.5 to 2.0mm from the

root of lead wires.

Temp. of solder: Lead Free Solder (Sn-3Ag-0.5Cu) 245±5°C

Appearance

Capacitance

Change

I.R.

No marked defect

Within ±10%

1000MΩ min.

Soldering

9 Effect

(Non-Preheat)

Dielectric

Strength

Per Item 6

Solder Temperature : 350±10°C or 260±5°C

Immersion time : 3.5±0.5s (In case of 260±5°C : 10±1s)

The depth of immersion is up to about 1.5 to 2.0mm from the

roof of lead wires.

Heat

Capacitor

Shield

1.5

to 2.0mm

Molten

Solder

Pre-treatment:

Capacitor should be stored at 125±2°C for 1h, and apply the

AC2000V(r.m.s.) 60s (in case of Type RA, apply the

AC4000V(r.m.s.) 60s) then placed at room condition* for

24±2h before initial measurements. (Do not apply to SL char.)

Post-treatment:

Capacitor should be stored for 1 to 2h at room condition*.

* "Room condition" Temperature: 15 to 35°C, Relative humidity: 45 to 75%, Atmosphere pressure: 86 to 106kPa

Continued on the following page.

19