DF9 View Datasheet(PDF) - HIROSE ELECTRIC

Part Name

Description

View to exact match

DF9 Datasheet PDF : 8 Pages

| |||

BPrecautions for Use

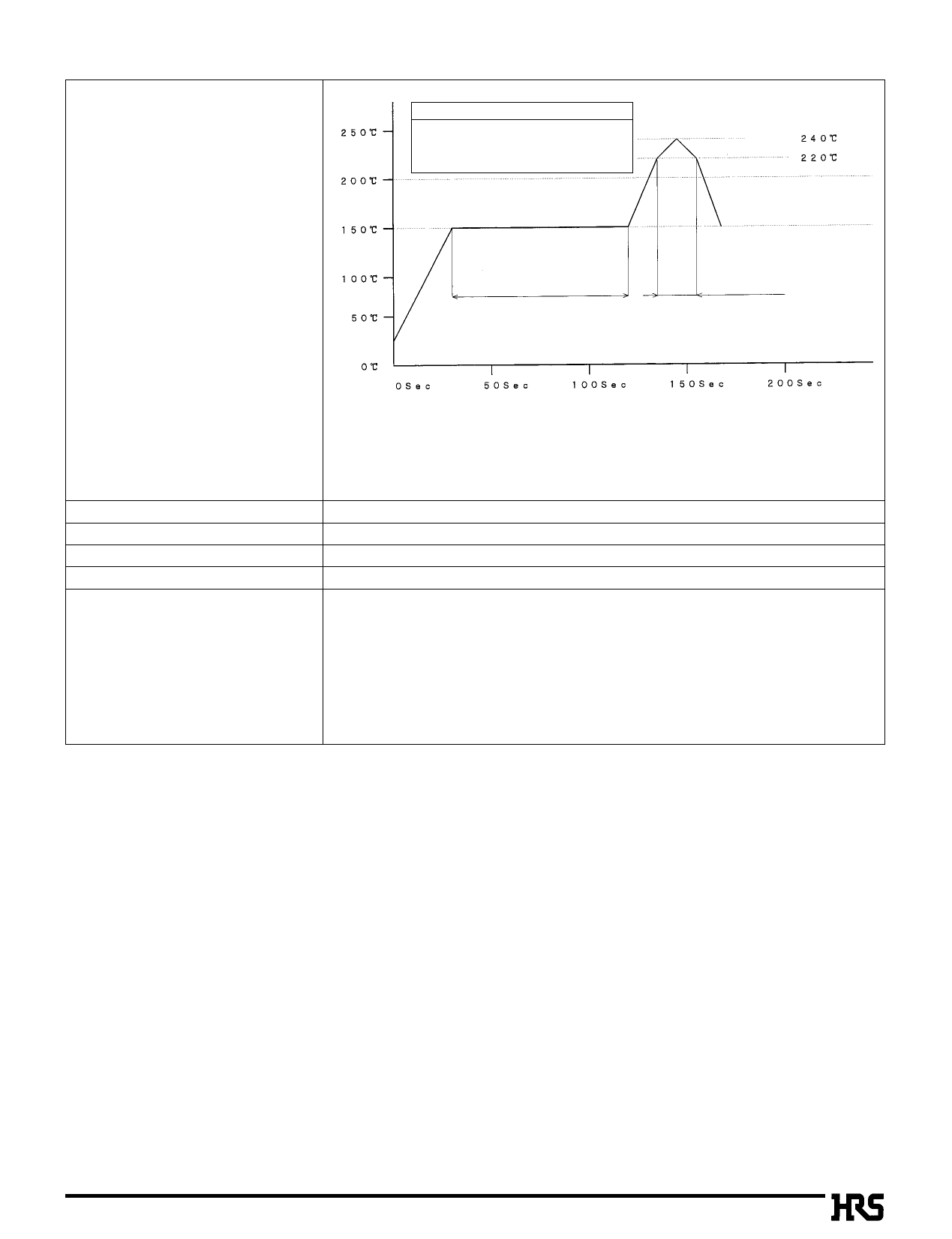

1. Recommended Temperature Profile (SMT) Temperature

IR reflow condition

Preheating area 150ç for 100 to 120 seconds

Soldering area 235±5ç for 10 seconds max.

220ç Min for 10 to 30 second

Maximum

Preheating area

Soldering area

Time

2. Recommended Manual Soldering Condition (SMT)

3. Recommended Screen Thickness (SMT)

4. Board Warp(SMT)

5. Cleaning Condition

6. Cautions

Note 1 : Maximum twice action is allowed under the same condition. However, the interval between

the first process and second actions must be maintained at the room temperature.

Note 2 : The temperature indicates the board surface temperature in the connector lead area.

Soldering iron temperature: 290±10ç, Soldering time: Within 2 seconds

0.15mm

Maximum 0.03mm in the connector center area, based on both connector edges.

Refer to the "Nylon Connector Use Hand book".

s Avoid retaining the board with the connector only, and fix the board by any other means than the connector.

s Where the board is not mounted, the insertion or extraction will cause damage or deformation in contacts.

s Excessive scoop insertion or extraction may result in damage.

s In the manual soldering process, don't carry out flux coating which will cause a flux blister on the connector.

s The color phase of this product may be slightly different from that of the forming product according to the

manufacturing lot. However, the difference doesn't affect the performance.

A285